In the modern electrical industry, tapes and adhesives have become essential components. With the continuous advancement of technology, the functions and complexity of electrical products have increased, and adhesive solutions in electrical manufacturing have become more widespread. Whether in the production of home appliances, commercial electrical products, or high-end electronic devices, the efficient performance of tapes and adhesives greatly enhances the quality, reliability, and safety of the products.

1. Precise Bonding and Structural Stability

Electrical products are typically composed of multiple components, and tapes and adhesives play a critical role in fixing these parts. For example, during the production of home appliances such as refrigerators, washing machines, and microwaves, tapes are used to secure components, ensuring they do not loosen during use. This structural stability not only enhances the durability of the products but also effectively reduces noise or vibration caused by loose parts, improving the user experience.

For instance, glass panels or plastic panels in home appliances often need to be bonded with metal components. Traditional screws or nails may affect the appearance and functionality. Using strong adhesive tapes and specialized adhesives ensures a firm bond without affecting the appearance, while also providing moisture and dust resistance. 3M 467MP tape, a high-strength double-sided tape, is commonly used in these precise bonding applications, ensuring long-lasting bonding performance.

2. Sealing and Insulation for Electrical Appliances

In terms of sealing and insulation, tapes and adhesives play an irreplaceable role. The outer casings of home appliances often need high sealing performance to prevent heat leakage and moisture ingress, which is critical for extending the lifespan and ensuring the safety of electrical appliances. For example, sealing strips on refrigerator and microwave doors often use high-seal tapes, not only to retain the cold air but also to reduce energy waste.

For electrical insulation applications, 3M 33+ Electrical Tape is an excellent choice. This tape provides outstanding insulation properties and is commonly used for electrical connections inside appliances to prevent short circuits and electrical failures. Its high-temperature and aging-resistant features make it particularly suitable for high-load home appliances, ensuring the appliance operates safely and stably over time.

Additionally, the circuit boards, wiring, and components inside appliances need to be insulated with adhesives to prevent electrical failures. For example, specialized electrical tapes are used in products like televisions, air conditioners, and washing machines to protect circuits, ensuring electrical safety and enhancing the long-term stability of the products.

3. Thermal Management and Heat Dissipation Solutions

As electrical products become more feature-rich, thermal management has become an essential consideration in design. Electronic components, such as chips and processors, typically generate significant heat, which must be dissipated effectively to avoid overheating, which could cause malfunctions or damage. Thermal conductive tapes and adhesives play a critical role in this process.

For example, in home appliances like air conditioners and refrigerators, thermal conductive tapes are used between electronic components and heat sinks to help efficiently transfer heat, ensuring the electrical devices operate at the optimal temperature. Additionally, 3M 8810 Thermal Conductive Tape is widely used in thermal management for electronic products, effectively reducing component temperatures and extending the appliance’s lifespan.

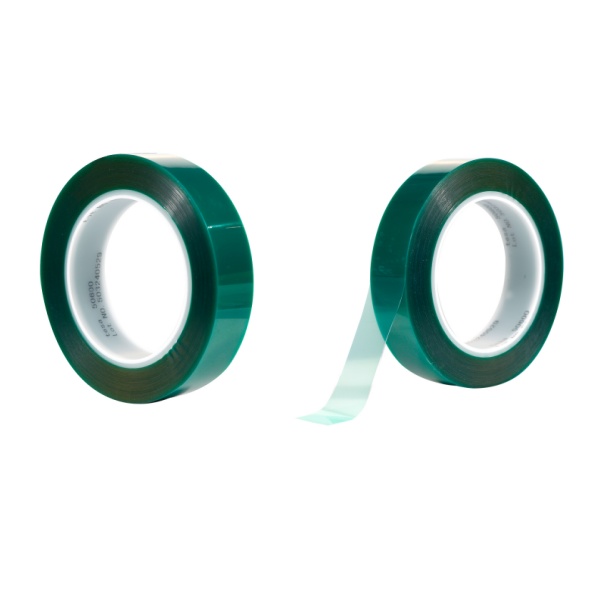

For high-temperature sealing and masking, tesa 50600 High-Temperature Masking Tape is an ideal choice. It maintains excellent stability under high-temperature conditions and is widely used in electrical manufacturing processes such as painting, spraying, and heat treatment. Its high-temperature performance ensures that electrical products are not affected by temperature fluctuations during production, providing more precise masking and protection, particularly for high-temperature components and sensitive parts.

Thermal conductive tapes can also be used in other devices requiring efficient heat dissipation, such as power tools, battery chargers, etc., ensuring that appliances remain stable during high-load operation.

Conclusion

In the electrical industry, tapes and adhesives are not just simple bonding tools; they play a crucial role in enhancing the performance, safety, and reliability of electrical products. By using high-quality tapes and adhesives, electrical manufacturers can effectively solve various complex technical problems, improve their products’ market competitiveness, and meet consumers’ high standards for quality, performance, and safety.

By appropriately selecting products like 3M 33+ Electrical Tape, tesa 50600 High-Temperature Masking Tape, 3M 467MP Tape, and others, electrical manufacturers can achieve optimal solutions at every stage of production, improving efficiency and providing a more stable, safe user experience for end customers.

Post time: Feb-27-2025